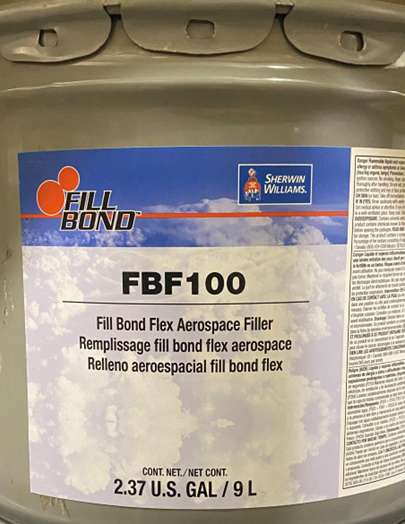

Fill Bond® Flex Aerospace Filler (FBF100) restores aircraft exterior composites by permanently concealing surface imperfections

ANDOVER, KANSAS – Sherwin-Williams Aerospace Coatings launched Fill Bond Flex Aerospace Filler (FBF100) as a new, convenient method for filling seams, rivets and small spot repair areas on aircraft prior to painting. The high-quality, two-component polyester filler kit is designed to block, and permanently conceal, surface imperfections on composite exterior aircraft surfaces. The lightweight filler provides performance, versatility and productivity by offering strong adhesion, resistance of shrinkage, sandability, flexibility and stain resistance, making it ideal for creating smooth surfaces for topcoat applications.

For ease of use, Fill Bond Flex Aerospace Filler comes in a mechanical dispenser package with an included hardener. The solution does not require priming and cures quickly, increasing shop productivity and reducing the process time for topcoat preparation. High Flexibility Body Filler is ideal for filling the weave structure of composite materials, as well as any dents, scrapes and scratches. The product is available in light gray and is compatible with Sherwin-Williams aerospace topcoats.

“When coating an aircraft, you want to hide every surface imperfection possible for a very smooth and aesthetically pleasing final finish,” said Julie Voisin, Market Segment Manager, Aerospace, Original Equipment Manufacturer Interior and Commercial Vehicle Refinish. “We’re making that process easier for composite aircraft with Fill Bond Flex Aerospace Filler, giving users a sag-resistant, cartridge-based application option that enhances their finishing speeds and delivers optimum results.”

For the best outcomes, applicators should abrade the surface or filler with an 80-grit sandpaper or via another comparable procedure. Then, they should apply the filler to a clean, dry surface that is free of dirt, dust, oil, grease and wax, using a plastic spreader. Thin layers should be applied to any damaged areas using firm pressure to ensure maximum adhesion. Additional layers should be added to build up damaged areas higher than the metal surface to allow for sanding. However, excessively thick layers in one application should be avoided. Surfaces should always be air-blown and tack-wiped to be painted.

For more information on the Fill Bond Flex Aerospace Filler, visit https://aerospace.sherwin.com or call Sherwin-Williams Aerospace Coatings at 1-888-888-5593 (North America), 1-316-733-7576 (international).