February 19, 2020 Oscoda, MI – When riveting, a hard surface to support the rivet is essential. The bucking bar is designed to deliver a durable, heavy support system during that process. If the metal alloy in the bar is too soft, it will wear quickly or not provide the necessary assembly backing. On the other hand, if the metal alloy is too hard, the bucking bar will break easily. Tungsten metal alloys are designed specifically for bucking bar applications.

Tungsten bucking bars, versus the conventional steel bucking bars, offer many benefits to the user. They weigh almost twice as much as those made from conventional steel which gives the ability to properly install a rivet in a confined space. Tungsten bucking bars also reduce the vibration that is typically caused when installing rivets. This allows the user to work in a comfortable position and for longer periods.

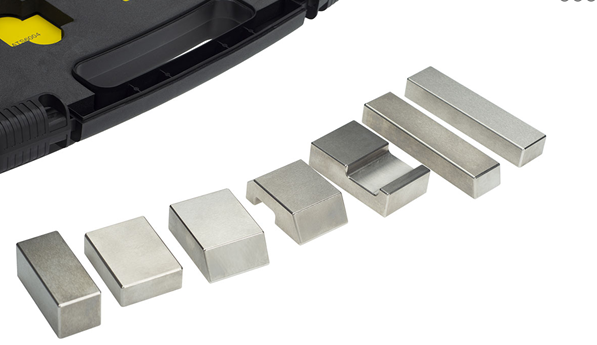

Aircraft Tool Supply carries seven Tungsten Bucking Bars in various dimensions, and weighs. You can shop the variety of Tungsten bucking bars that ATS has to offer by going to www.aircraft-tool.com today.

For more information regarding Aircraft Tool Supply products, please visit www.aircraft-tool.com.